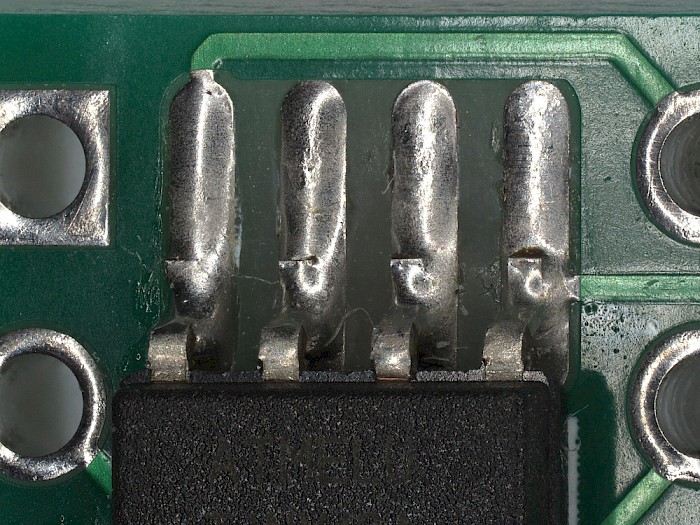

Solderability Test

This covers the solderability of component leads by simulating industrial soldering processes in a laboratory reflow oven, ensuring impeccable solderability.

The vast majority of components are contacted and fixed to the PCB by soldering. An absolute prerequisite for flawless electrical connections and mechanical stability are perfectly wettable component leads and PCB pad surfaces with solder. If this is impaired, i.e., if the surfaces do not accept any or only insufficient solder, smooth processing of the components is not possible.

A solderability test provides reliable information on whether the components can be soldered in series production according to regulations and without problems. In SafeLab, we use a special reflow soldering oven for these analyses, enabling particularly practical soldering tests – also with customer-specific soldering profiles on request.

We generally recommend this inspection for these cases: if the age of the components exceeds the manufacturer's approval, if there are doubts about the correct packaging and storage, or if our experts find optical anomalies during the visual inspection.